THE DEVELOPMENT OF THE “RELIANT” MANDOLIN TREMOLO OR VIBRATO ARM ®

The notion of making a tremolo or vibrato arm for an electric mandolin had been at the back of my mind for a while, gathering dust in the remaindered bin of my brain. Quite by accident it materialised one day out of the blue as I was in my workshop, concentrating on something else. At some time I had been given a box of metal offcuts, amongst which was a length of C channel steel, the kind of thing used in an industrial cable mounting system. On my workbench at the same time was a pile of springs from a car’s braking system, in this case the shoe hold down springs. Whilst waiting for that something else to happen, I absentmindedly picked one of the springs up and slid it into the track. It was a snug enough fit for the spring to be held in place. I slid a couple more in, and whatever was supposed to be happening happened and I left it to one side. Later, in the general chaos of my workshop it had flipped over and was sitting on the springs. When I touched it , the whole thing wobbled. This, I realised, could be the basis of a tremolo unit if it was anchored somehow to the top of an instrument. This was achieved by slicing off a section of the C channel, flipping it over and sliding it into the C channel behind the springs. Two screw holes were drilled to hold it in place.

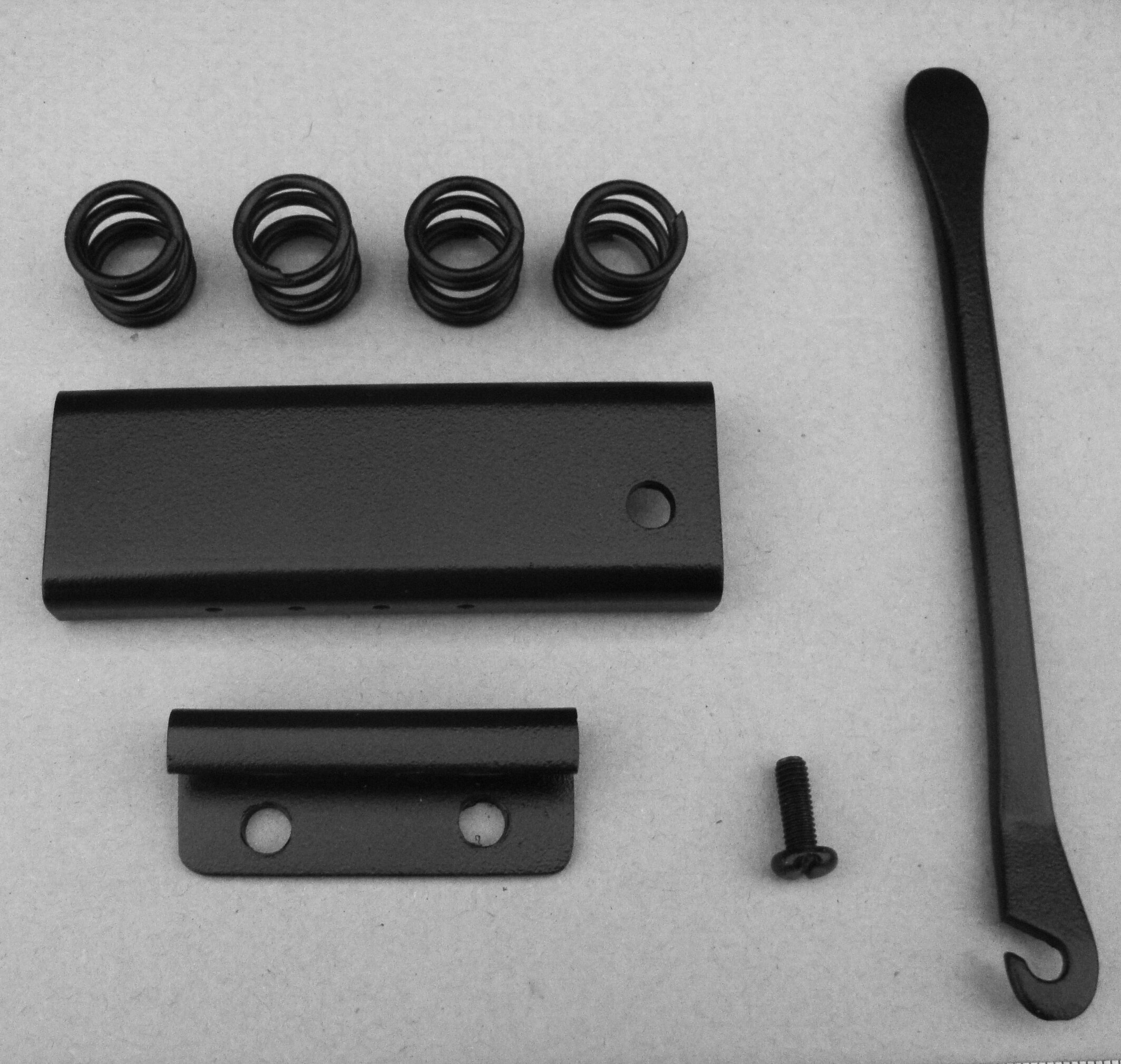

The strings would be secured to the spring unit on 2mm brass pegs inserted in to the rear of the unit with the springs passing forward over a bridge fixed to the top. Making a special jig meant I could drill four equidistant 2mm holes. It should in theory work, but the results when put under string tension still had to be seen, I set up a test rig, and tuned the whole lot up to concert pitch. To my amazement , the tension pulled the whole unit exactly parallel with the top, which was precisely what I was looking for. I still needed some sort of tremolo arm, and toyed with the idea of using a stock item, but these proved too big. Again, in the dusty recesses of my brain, I had a picture of a short metal bar with a notched hole in one end, but what , and where, was it. After much emptying of boxes I found it in a toolbox. A Dunlop bicycle tyre lever, which I had carried around for thirty odd years. Once attached with a bolt, this worked better than expected, with the slot for the spokes meaning it could be easily removed. In order to move things on I needed to source some new parts, notably springs and levers. On the spring front I discovered that just about every make of car had it’s own size of hold down spring. I tried a few, but the height of the spring was critical, too small and the unit grounded on the top, too tall and it became unstable. The original springs came off a Reliant Rialto Supervan 111, (hence the name) and spares for these were hard to come by. Searching auto parts shops for a bag of springs for a Reliant caused a few raised eyebrows, but finally produced some Ford springs which were the same size. Again with the tyre lever, Dunlop ones seemed to have disappeared, but I finally sourced something similar from China. Black powder coating finished the unit off nicely.

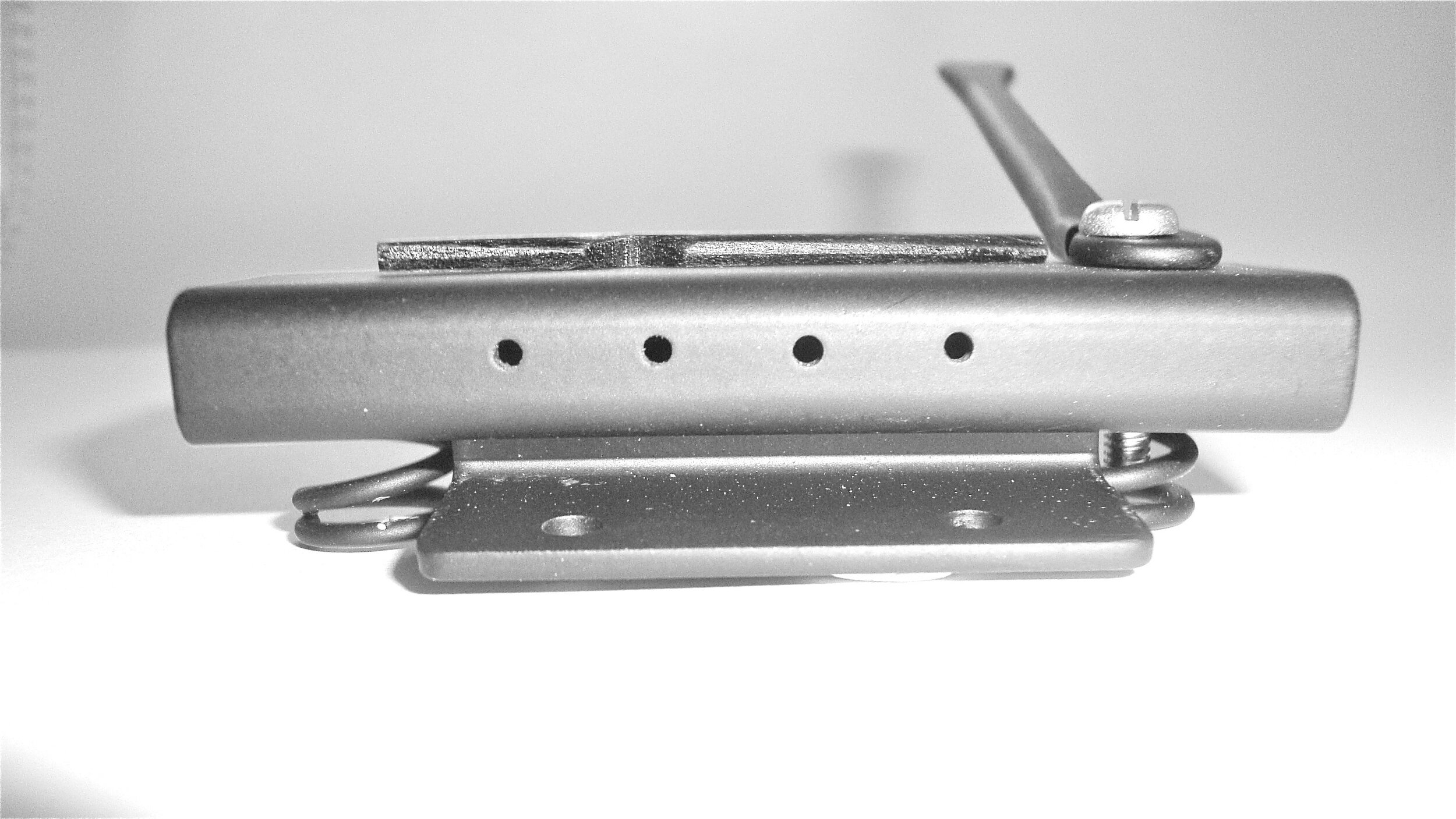

The prototype fitted to The Rippy Red Four String

A Mark 11 model was built to enable the unit to be used with the “Dolphamatic” adjustable bridge.